The resistance ability to water absorption is a key benefit of closed cell sponge rubber. Below, there is a short review explaining the different qualities of each one.

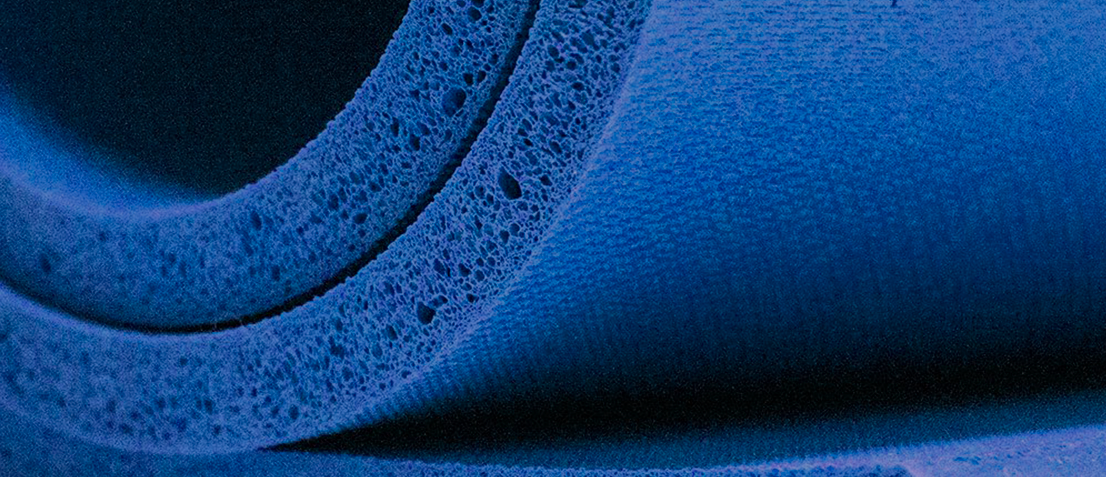

Closed Cell Sponge Rubber

This kind of rubber has a gas generator element in its manufacturing. When it crosses the heating zones in the curing system, it reaches a temperature which makes the blowing agent to degrade and allows the formation of gas bubbles, creating individual cellular structures within the rubber.

Closed cells are independent from each other. They have its own arrangement and they do not share any of its structures with other cells.

Closed cell rubber do not allow fluids to filter, hence it floats on water. It resists water absorption even when it is fully immersed. This is an important quality to avoid the filtration in building openings and construction applications, where water absorption could damage the building finishes and cause expensive repairs.

Open Cell Sponge Rubber

Open cell sponge rubber has distinctive open cells interconnected with neighboring cells. This allows a fast filtration of air and humidity, and also gives the rubber its liquid absorption property and the capacity to recover its original shape after compression.

As regards its use, open cell sponge rubber is generally applied in machines that use vapor pressure and it is also used as shock-absorber in a wide variety of fields.